HISTORY & PROVENANCE

The Holtzapffel dynasty of tool and lathe makers was founded in Long Acre, London by a Strasbourg-born turner, Jean-Jacques Holtzapffel, in 1794. The firm specialized in lathes for ornamental turning but also made a name for its high-quality edge and boring tools.

John Jacob Holtzapffel (1768–1835).

Moving to London from Alsace in 1792, Jean-Jacques worked initially in the workshop of the scientific-instrument maker Jesse Ramsden, anglicizing his name to John Jacob Holtzapffel. In 1794 he set up a tool-making partnership in Long Acre with Francis Rousset, trading under the name of John Holtzapffel. From 1804 he was in partnership with the Mannheim-born Johann Georg Deyerlein until the latter’s death in 1826, trading under the name Holtzapffel & Deyerlein.

Holtzapffel sold his first lathe in June 1795, for £25-4s-10d, an enormous price at the time. All of Holtzapffel’s lathes were numbered and by the time he died in 1835, about 1,600 had been sold. The business was located at 64 Charing Cross, London from 1819 until 1901 when the site was required “for building purposes”. The firm then moved to 13 and 14 New Bond Street, and was in premises in the Haymarket from 1907 to 1930.

John’s son, Charles Holtzapffel (1806–1847) joined the firm in 1827, at around which time the firm became known as Holtzapffel & Co.] Charles continued to run the business after his father’s death. He set about writing a treatise entitled Turning and Mechanical Manipulation, eventually running to some 2,750 pages, and which came to be regarded as the bible of ornamental turning. The first volume was published in 1843, but the final two volumes were completed and published after his death by his son, John Jacob Holtzapffel (1836–1897). There is some evidence to suggest that Francis Ronalds assisted Charles in the early stages of preparing the treatise. Typeset sections survive of an unfinished “Turner’s Manual” that Ronalds wrote in 1837 and there is marked similarity in the two prefaces and elsewhere. Ronalds and Charles also collaborated on developing lathe accessories.

When Charles Holtzapffel died in 1847 his wife Amelia ran the business until 1853. John Jacob II, the son of Charles and Amelia, was head of the firm from 1867 until 1896. A nephew of John Jacob II, George William Budd (1857–1924) became head of the firm in 1896. His son John George Holtzapffel Budd (1888–1968) later ran the business. By the early twentieth century, ornamental turning was going out of fashion, and the firm sold its last lathe in 1928.

No. 2245 was built and sold to its first owner in 1870. There have been six “custodians” of this beautiful lathe prior to me acquiring it in 2022. The owners of the lathe are as follows.

1870: George Charles Spencer-Churchill

1893: Hon. Osbert William Craven

1925: William George Collins

1956: C.W. Jowett

1970: T. Vaughn Anthony

1978: J. Malcolm Wild

2022: Scott B. Barrett

When I spoke with Malcolm about purchasing his lathe there was a sense of sadness that he conveyed regarding the departure from the United Kingdom. No. 2245 spent its first 152 years in the country from which it was built. Now crossing the Atlantic Ocean to begin a new chapter in the USA was a sad thought for him. I tried to soften the emotion by assuring him that I would be respectful of the task to keep this fine machine intact and in good working order.

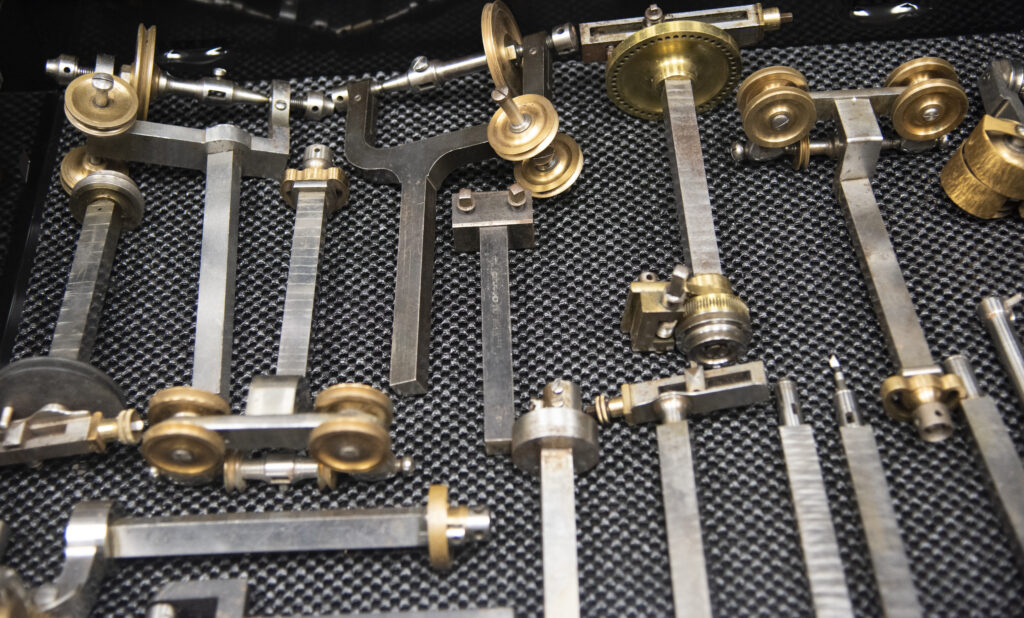

The lathe by itself has history. That history is added to by the collection of tooling that has been with it from the beginning. There could be a tendency by some to begin “parting out” chucks, cutting frames, or slides that are not often used. I assured Malcolm this would never be a thought that I would entertain. When it is tine for No. 2245 to find a new custodian, it will be as complete as it came to me, if not more so. I am thrilled at the opportunity to learn and grow in the world of OT with this fabulous collection of the best in the world tooling.

MY JOURNEY

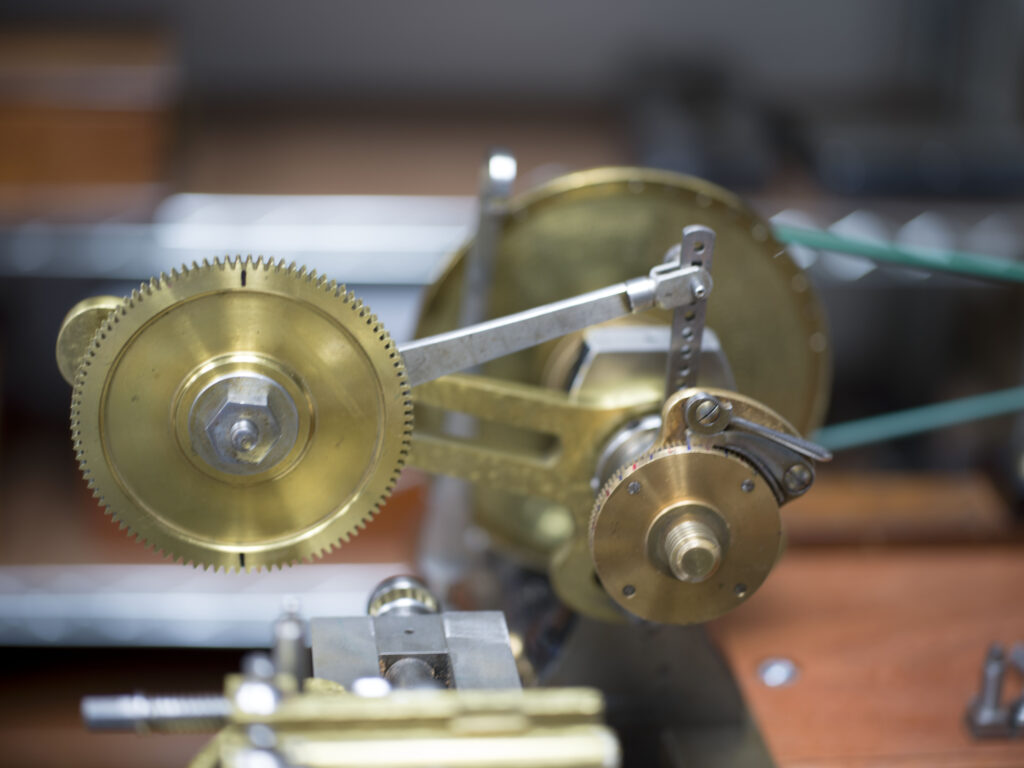

April 29 – May 2, 2022: Drove to David Lindow’s shop in Lake Ariel, PA to begin the process of preparing my new lathe for its journey “home”. Together we assembled the lathe and began to access what would be necessary to get it up and running. A new overhead pulley system was machined along with parts for the existing u-joint system for the spherical slide. Christian Lindow spent a full day making adapters to facilitate mounting my chucks to the Holzapffel and Holtz chucks to the Lindow Rose Engine along with the simple wood lathe. Monday morning the lathe was disassembled, parts were wrapped and packed for the journey to Illinois.

May 6: The lathe was unloaded from my car and gently placed in my shop. With the help of my loyal friend, Jim Bodman everything made it safely inside. I spent the rest of the day putting the lathe back together, relying on my memory from the week before.

May 20-21: I spent many hours building the slow speed drive system for the spindle. I machined the parts twice and finally achieved dependable rotation of the spindle.

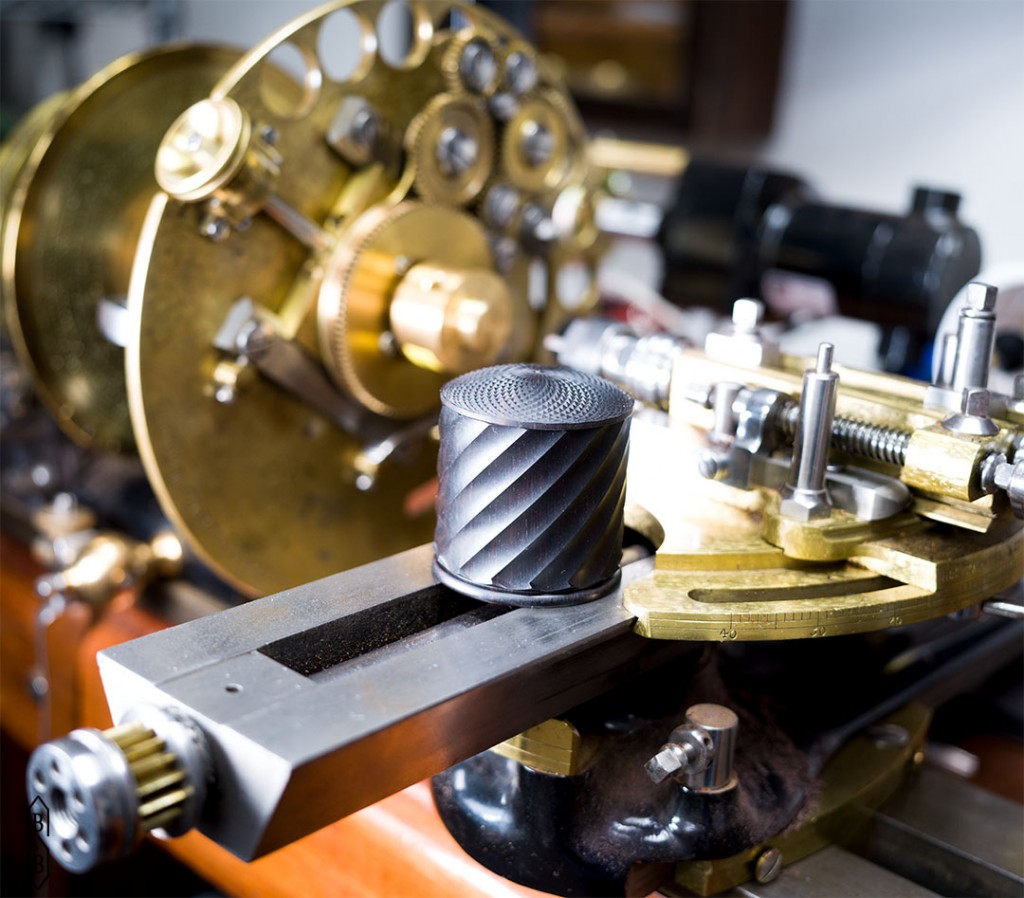

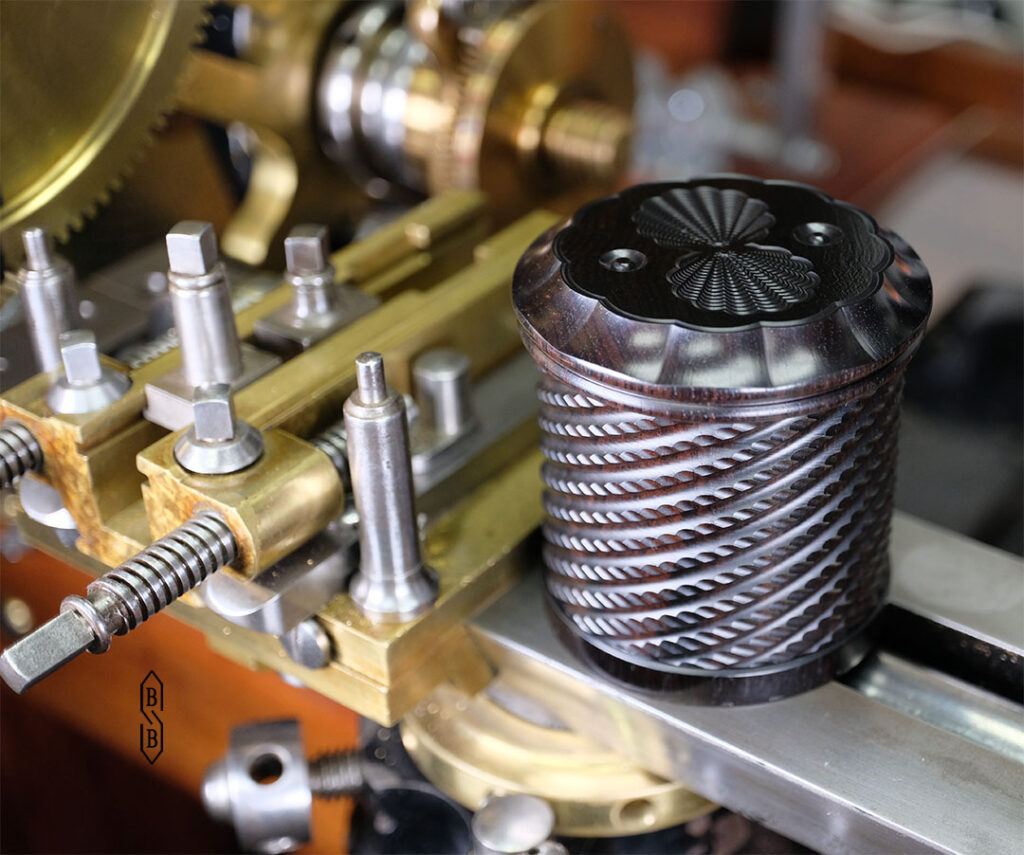

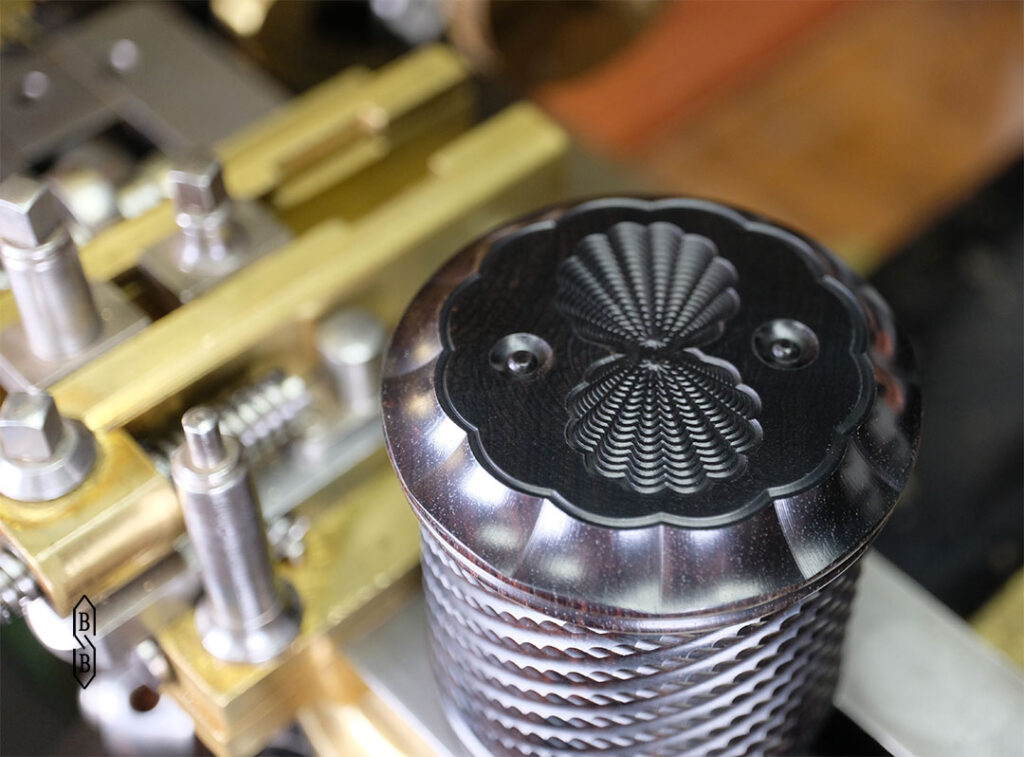

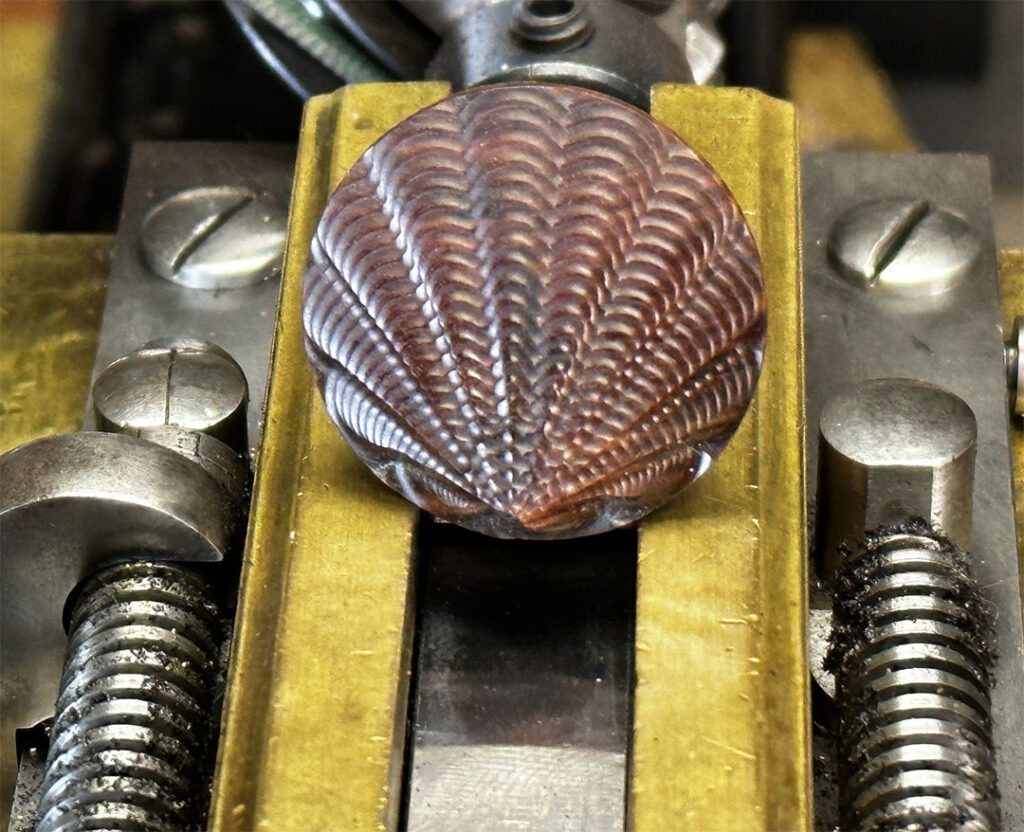

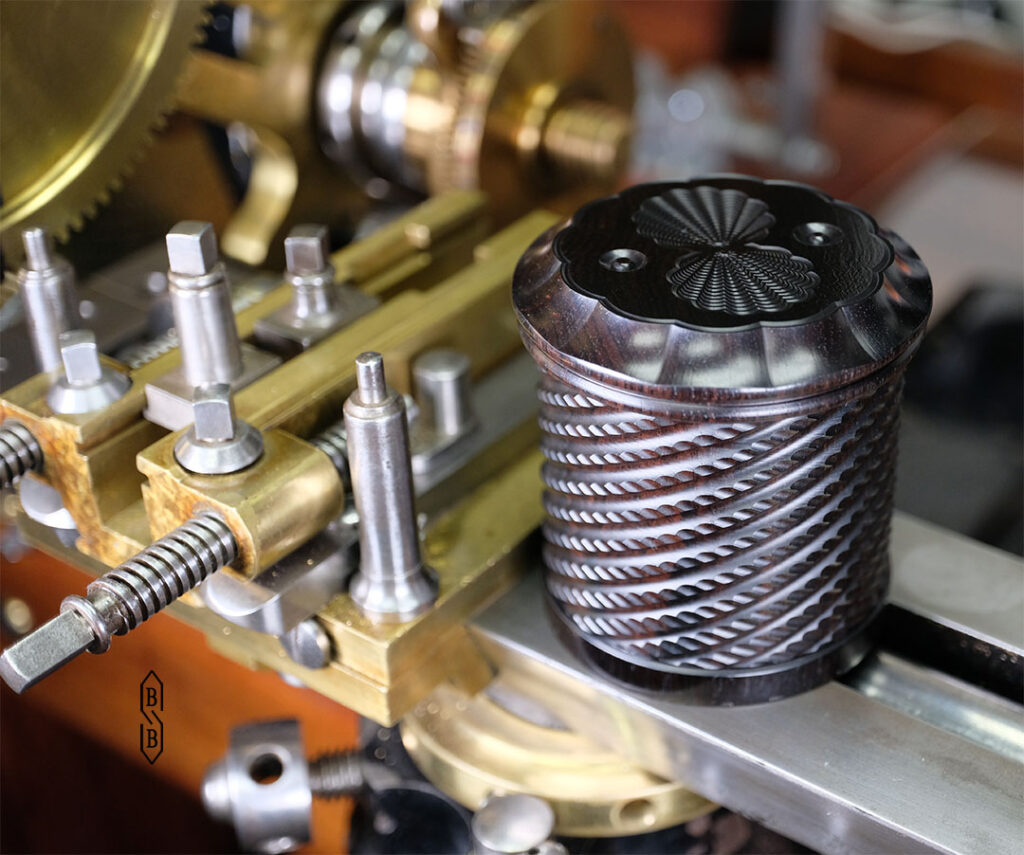

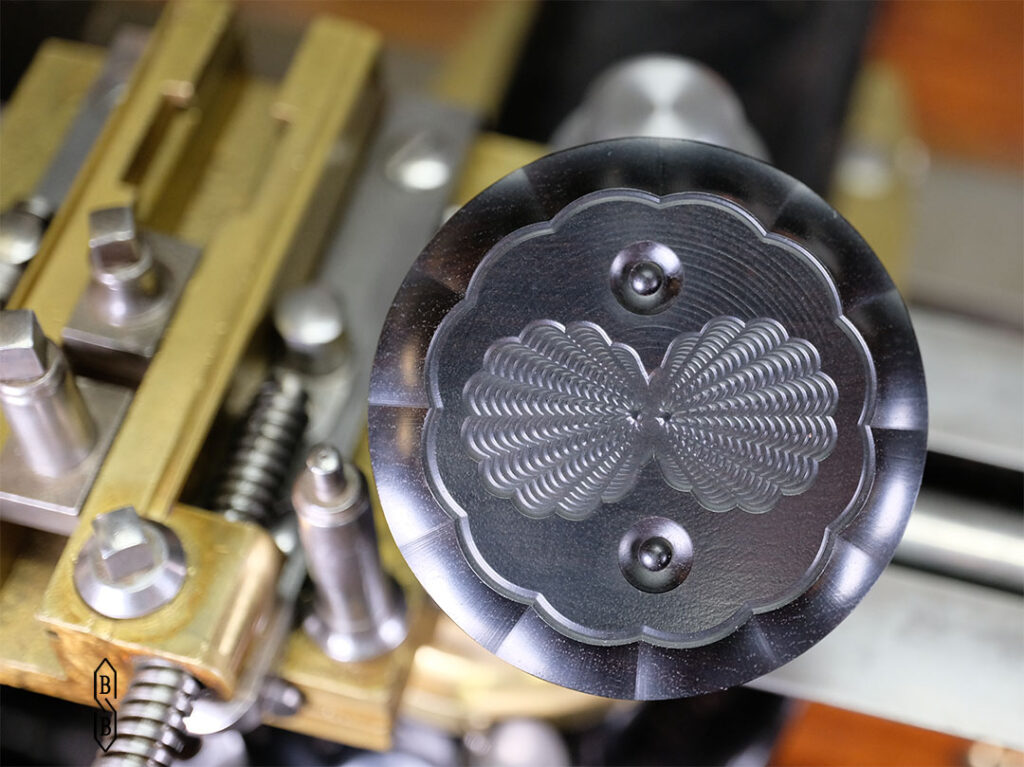

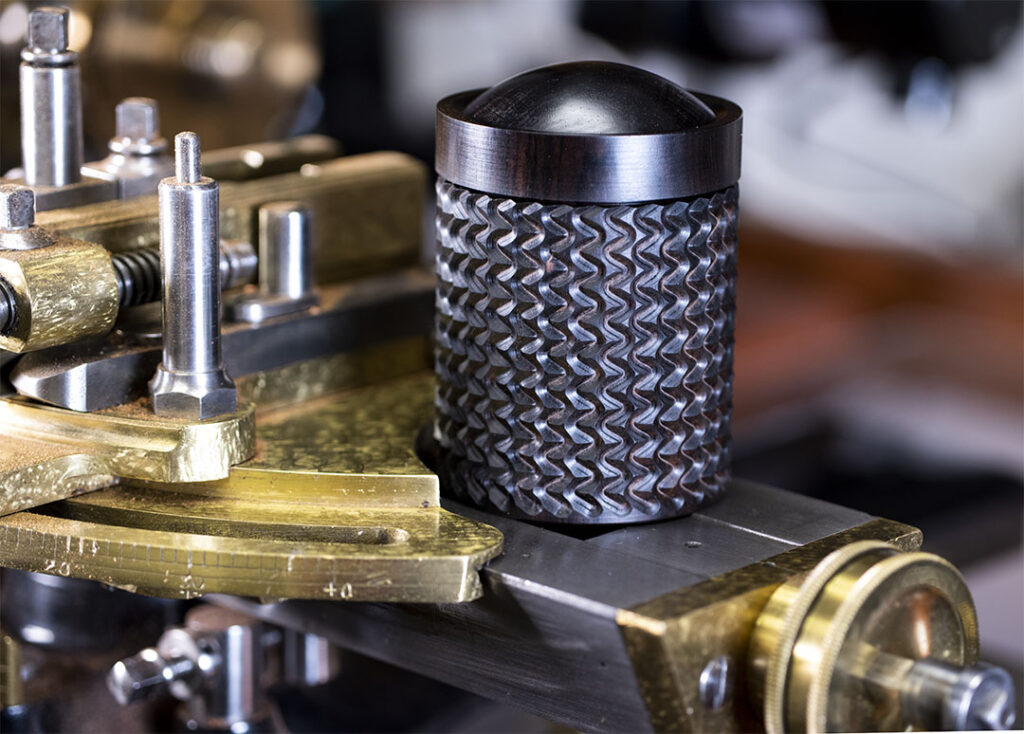

May 29: My first completed project was completed using a combination of lathes. An African Blackwood blank was prepared on the South Bend metal lathe. It was moved to the Holtzapffel where I set up the reciprocator. The box was completed using a pattern of 16 cuts phased 180 degrees between each cut. The lid was made to fit on the South Bend then decorated on the Lindow Rose Engine with an eighteen lobed pumping rosette. Once the first series of cuts were finished I phased and cut another series. The result was not acceptable so I skimmed it off and recut using a 120 degree cutter. This resulted in a much finer lid. Even though my mentor noticed the cutting frame was low, I was pleased with the outcome. I will recalibrate my cutting frame for future projects.

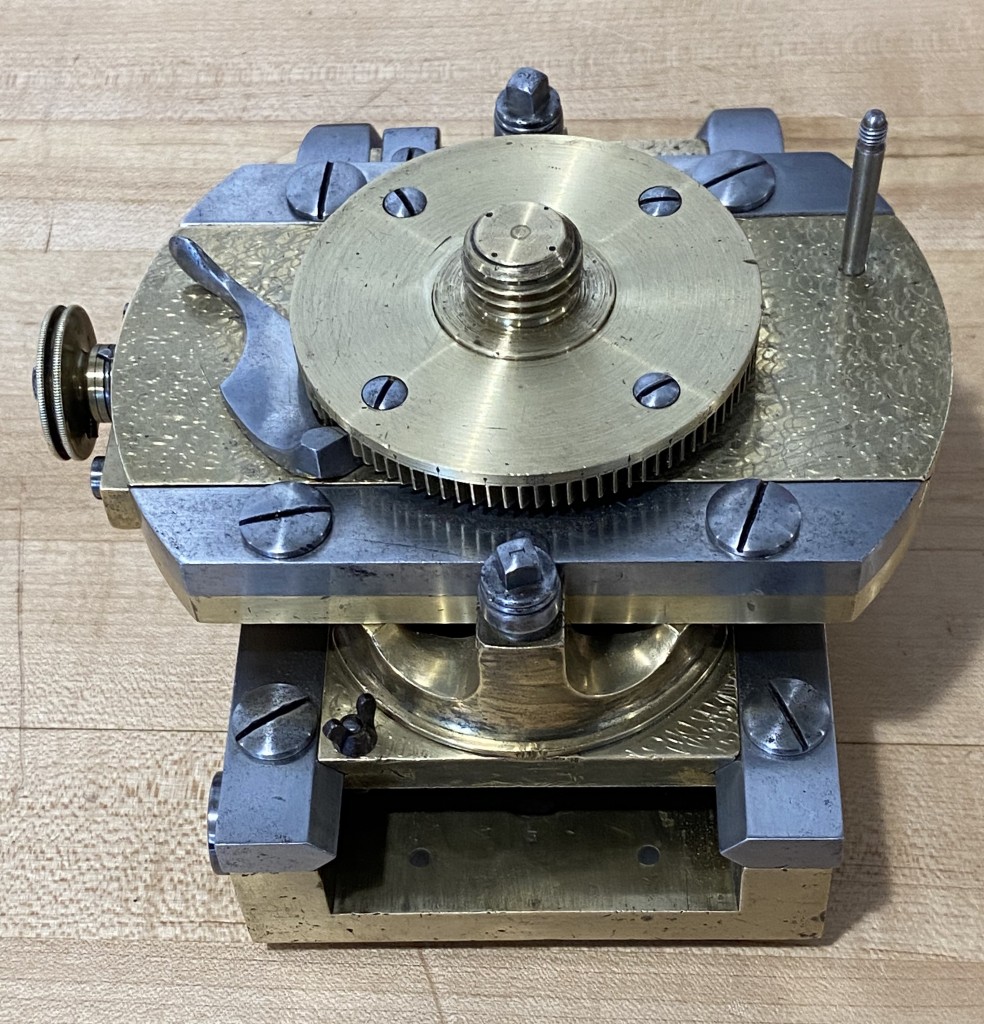

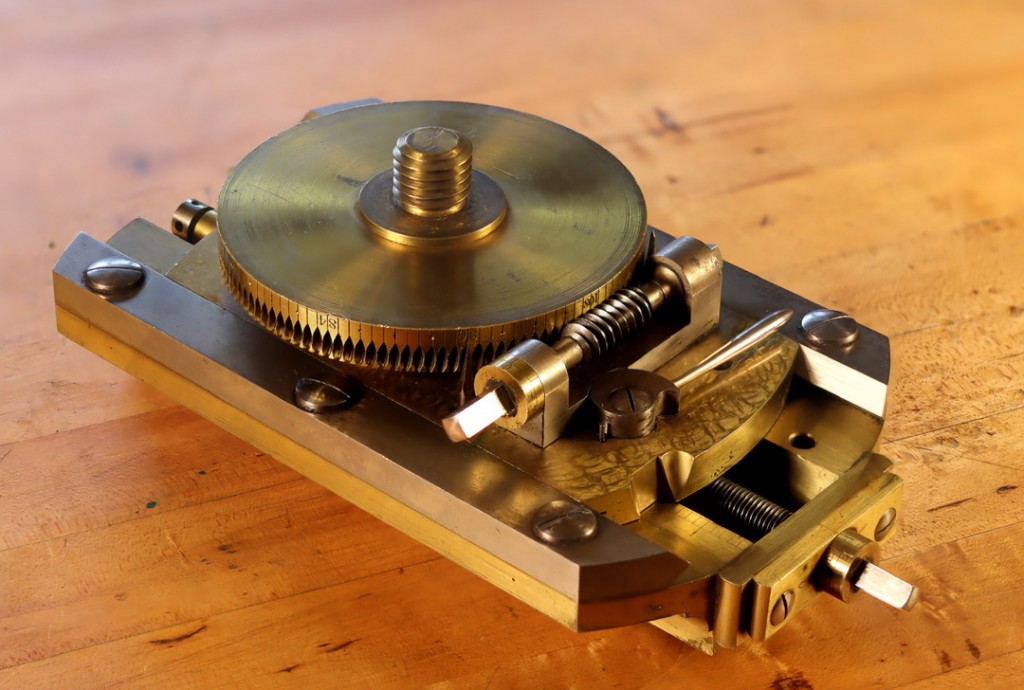

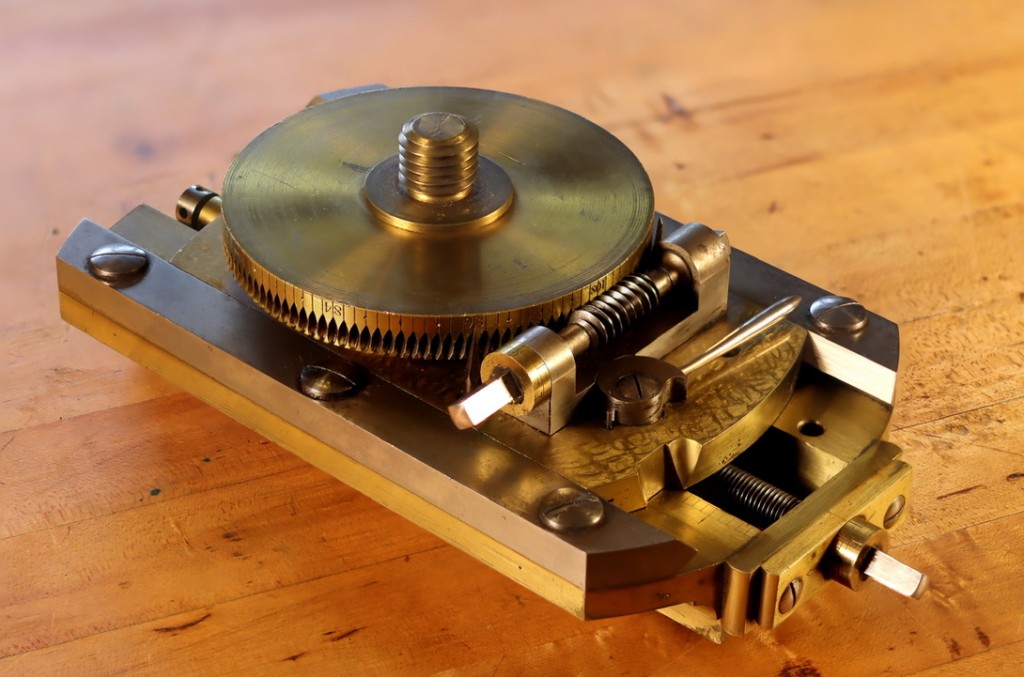

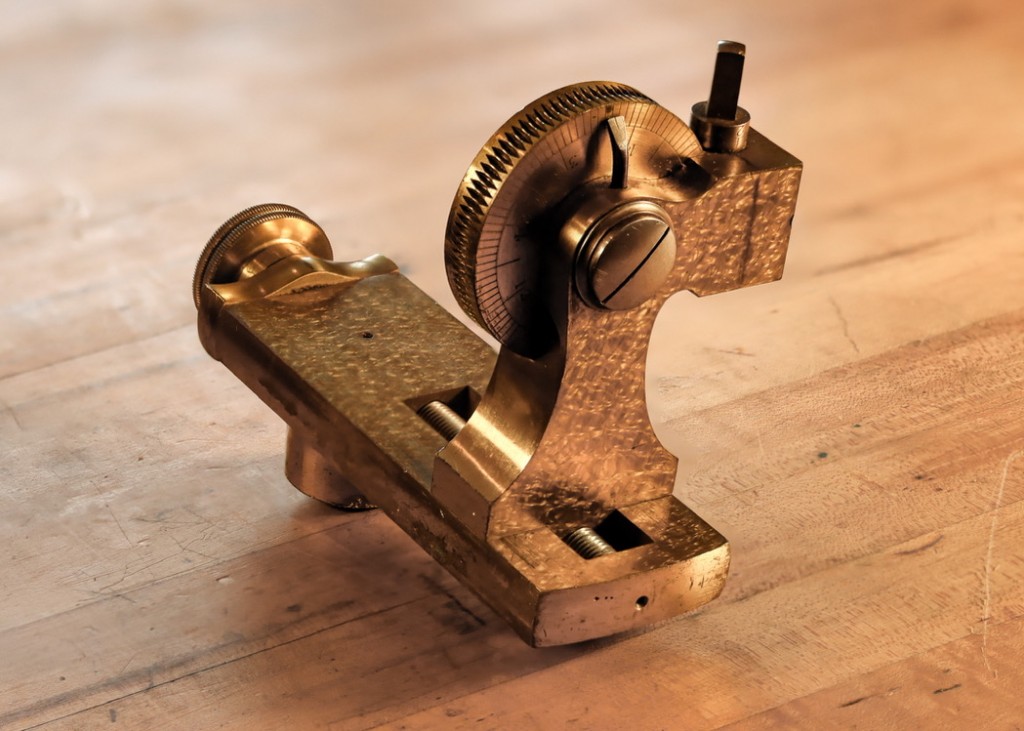

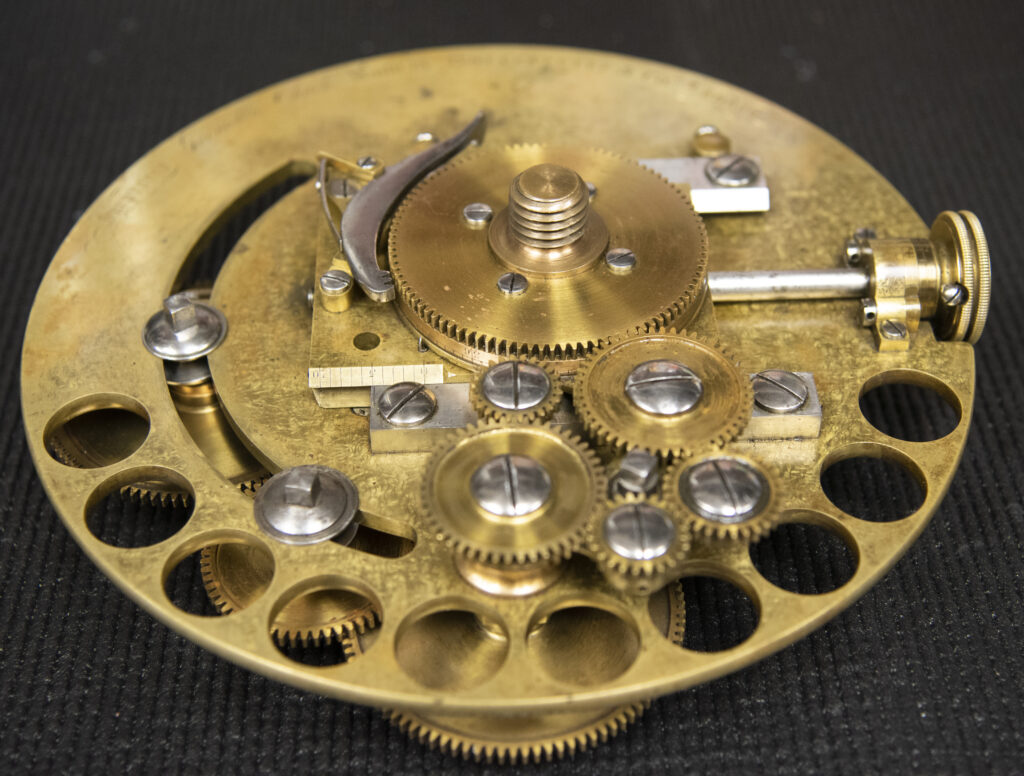

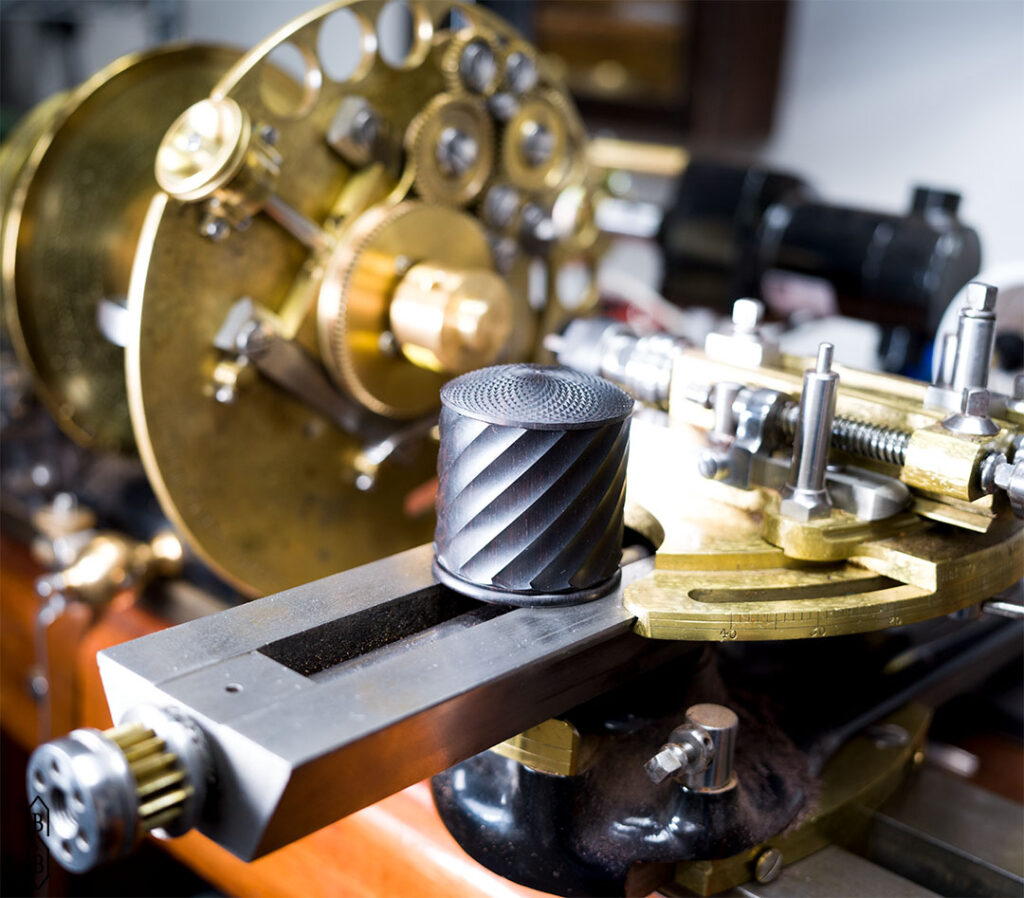

LATHE AND TOOLING

CLICK ON IMAGE TO ENLARGE

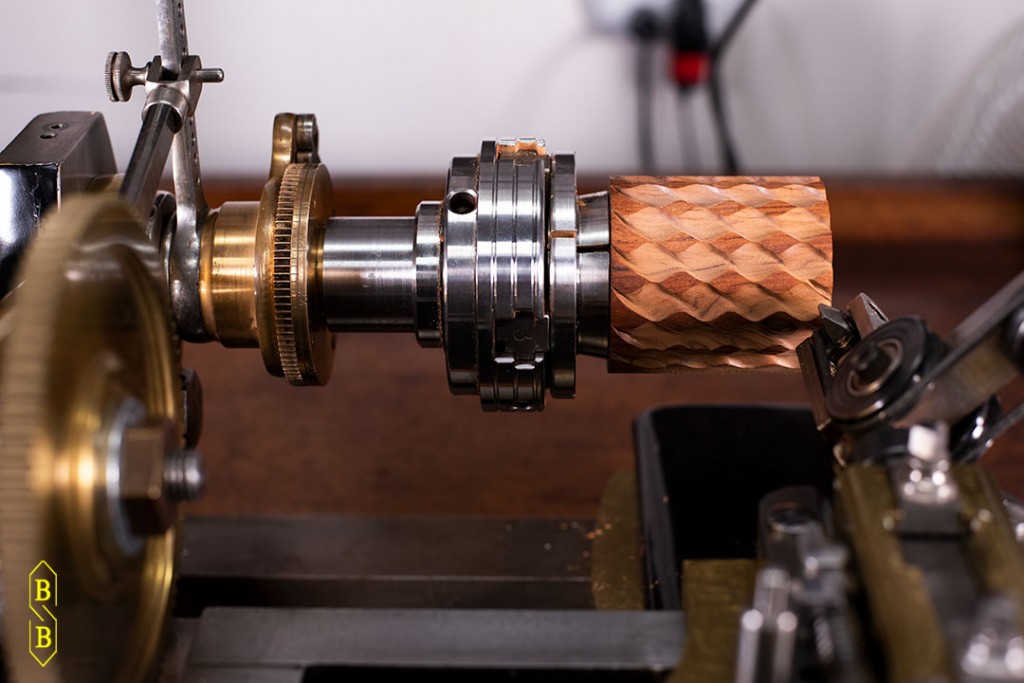

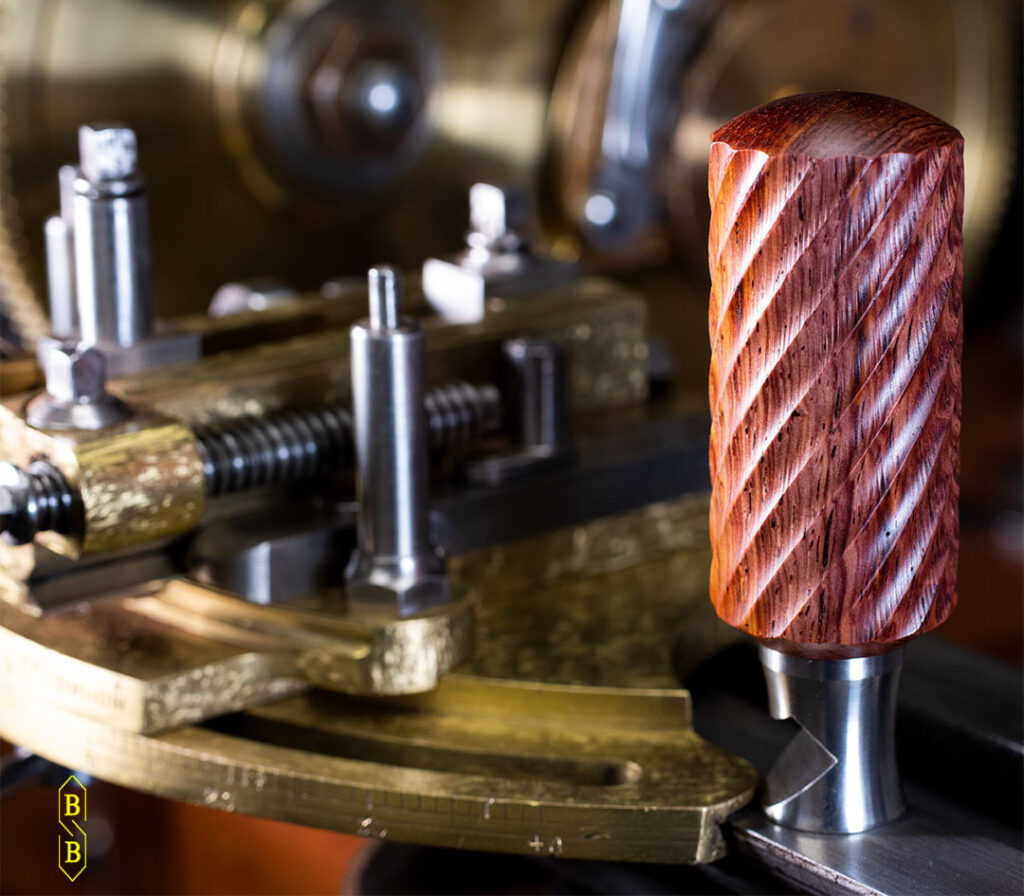

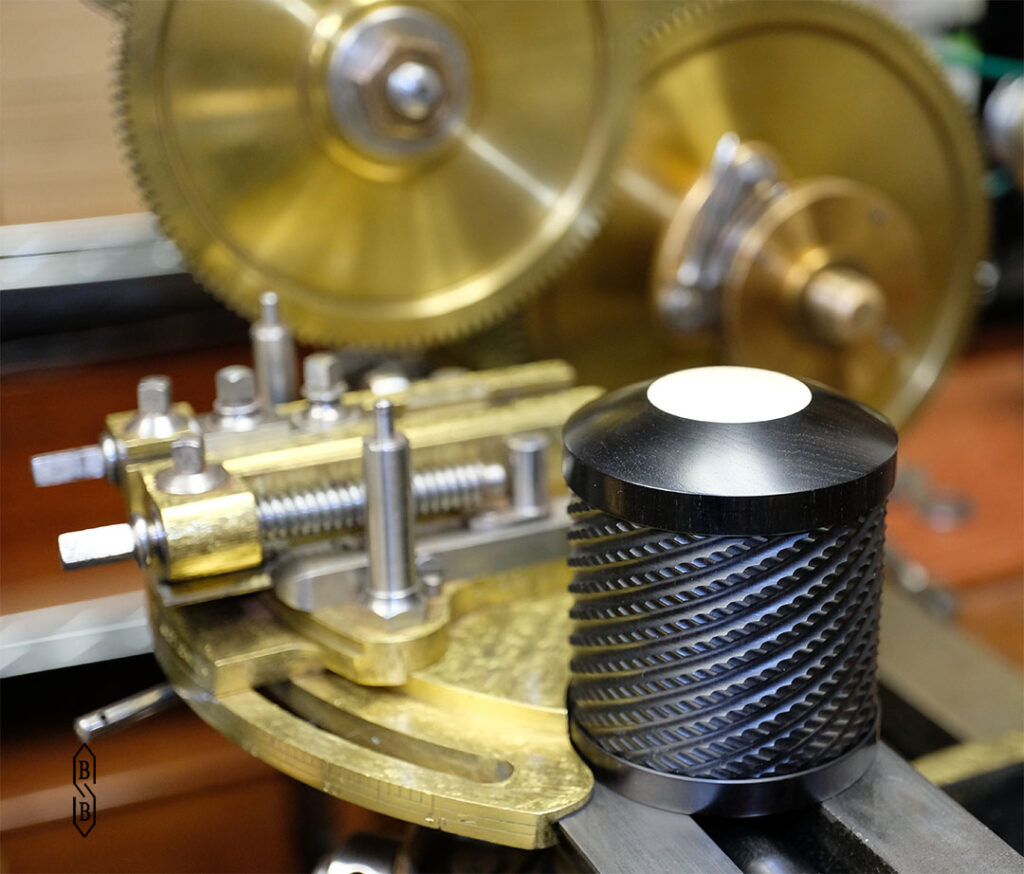

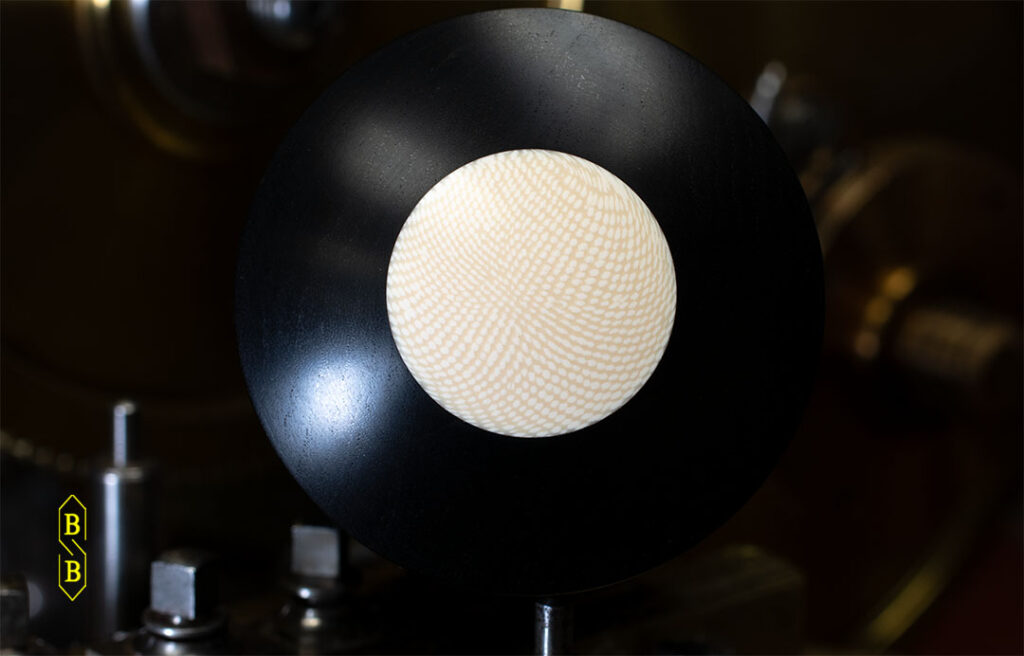

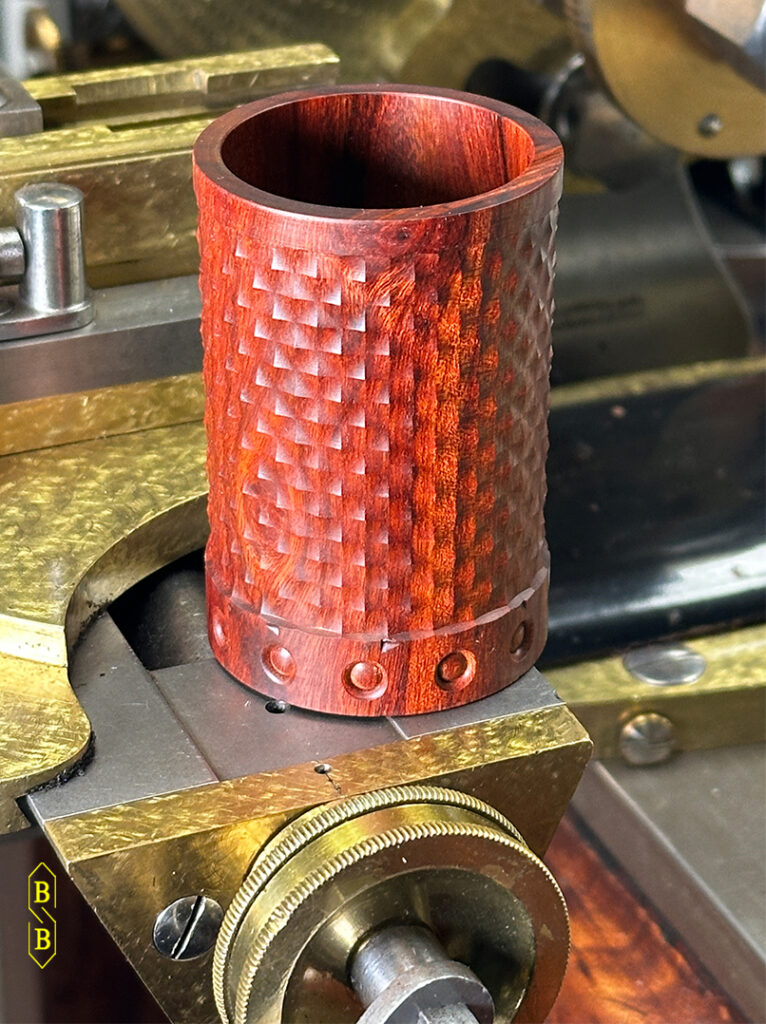

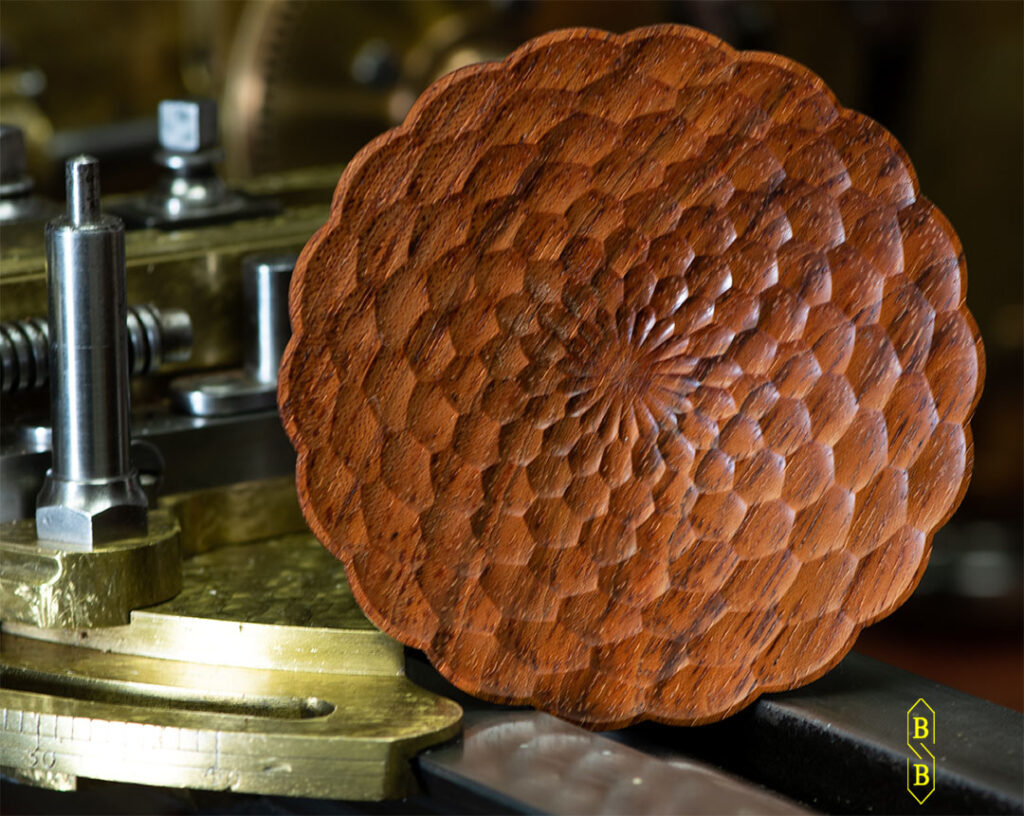

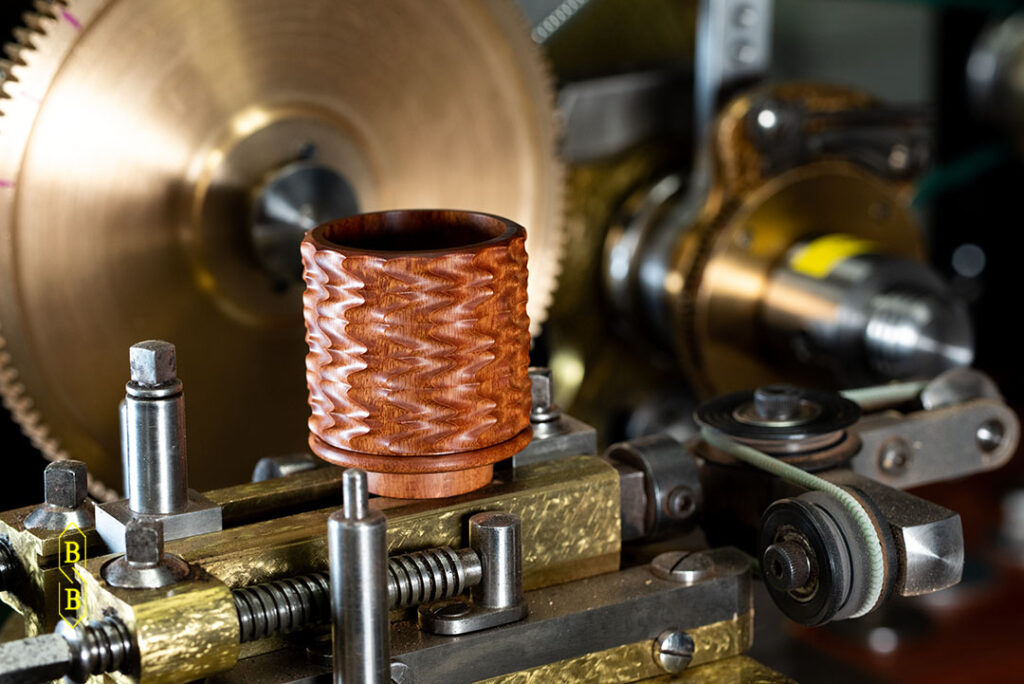

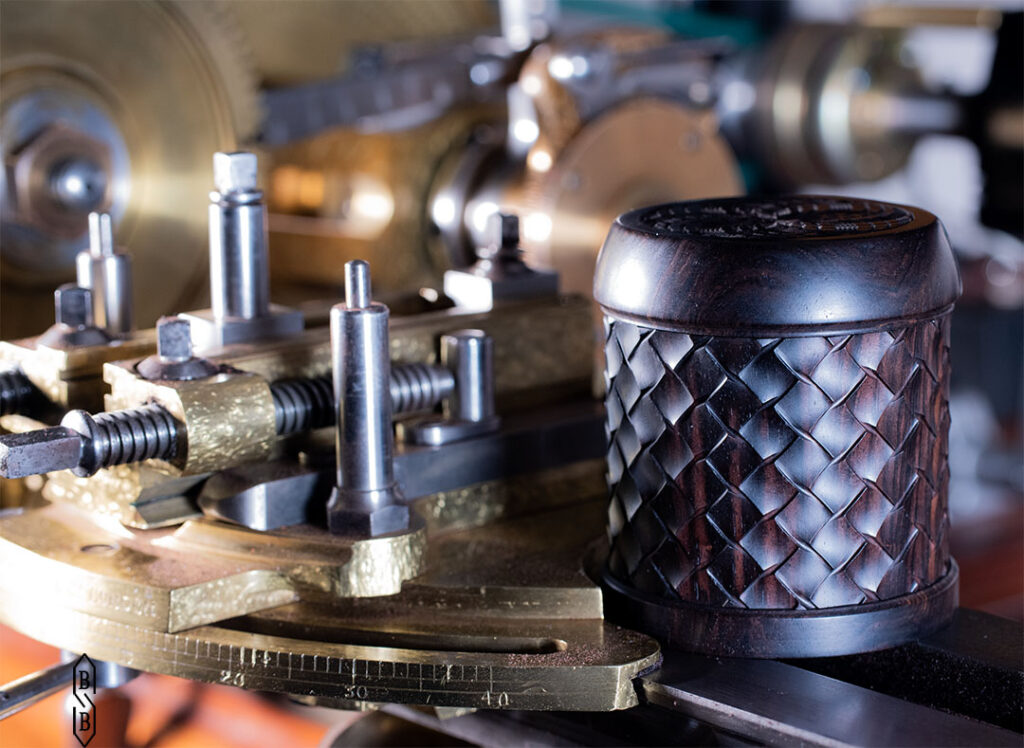

CURRENT PROJECTS

CLICK ON IMAGE TO ENLARGE

ORNAMENTAL TURNING LINKS

| Name | Link |

|---|---|

| Lindow Machine Works | VISIT |

| Plumier Foundation | VISIT |

| Ornamental Turners International | VISIT |

| Ornamental Turnings by David Lindow | VISIT |

| MADE Ornamental Rose Engine | VISIT |

| Society of Ornamental Turners | VISIT |

| Ornamental Turning History | VISIT |

| Ornamental Turning Book of Knowledge | VISIT |

| Memoria Technica - Brittany Nicole Cox | VISIT |

| Jon Sauer - Ornamental Turner | VISIT |